Technical Information

Technical Information Power And Control Cables

Power And Control Cables Power Appendixes

Power Appendixes CABLING ; Tools , procedure , accessories , laying and handling

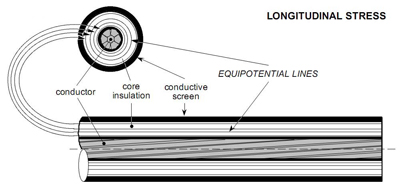

CABLING ; Tools , procedure , accessories , laying and handling Cable Stress Relief

Cable Stress Relief صفحه Cable Stress Relief

|

CABLE STRESS RELIEF A radial stress which can be represented by lines of flux and a longitudinal stress which can be considered as lines of equipotential |

|

|

|

|

|

When the semi-conducting core screen is cut, the electrical field distribution changes radically. The surrounding air becomes overstressed as does the dielectric material in the cable immediately in the vicinity of the cut screen. To prevent rapid breakdown of the cable it is necessary to apply a stress cone or a linear stress relief tube at the end of the screen. The cone has an insulating portion to reinforce the primary cable insulation and a conductive portion to mate with the semi-conducting core screen. This controls the lines of equipotential so that when they finally emerge into the air they are sufficiently far apart not to cause ionisation |